About OXSENSIS

Oxsensis – Measures more, in extreme conditions, leading the way in optical sensor technology for Industrial, Energy, and Aerospace applications.

Technology Leadership

Expert Advice

Proven Benefits

We work with industry leaders including Rolls-Royce, GE, Parker Aerospace, Wika.

![]()

Proof of technology

- Sensors demonstrated >1000°C in gas turbine combustor conditions

- Dynamic pressure measured to 2×10-5 of Full Scale pressure from 3 bar to 56 bar applications

- Simultaneous measurement of dynamic and static pressure, with temperature, demonstrated up to 1000°C in gas turbines

- Sensors are EMI Immune

Endurance demonstration in gas turbines

- Over six year’s of utility power generation operation to date

- Instrumentation experience on over 7 types of industrial and aero gas turbines to date

- Industrial gas turbine OEM New Product Introductions

Our production areas are semi-clean rooms dedicated to optical component fabrication and sensor assembly. The Test Laboratory is fully equipped to test and calibrate sensors. High frequency dynamic pressure testing is accomplished using our Shock Tube facility and our Environmental Chamber allows us to fully evaluate system stability.

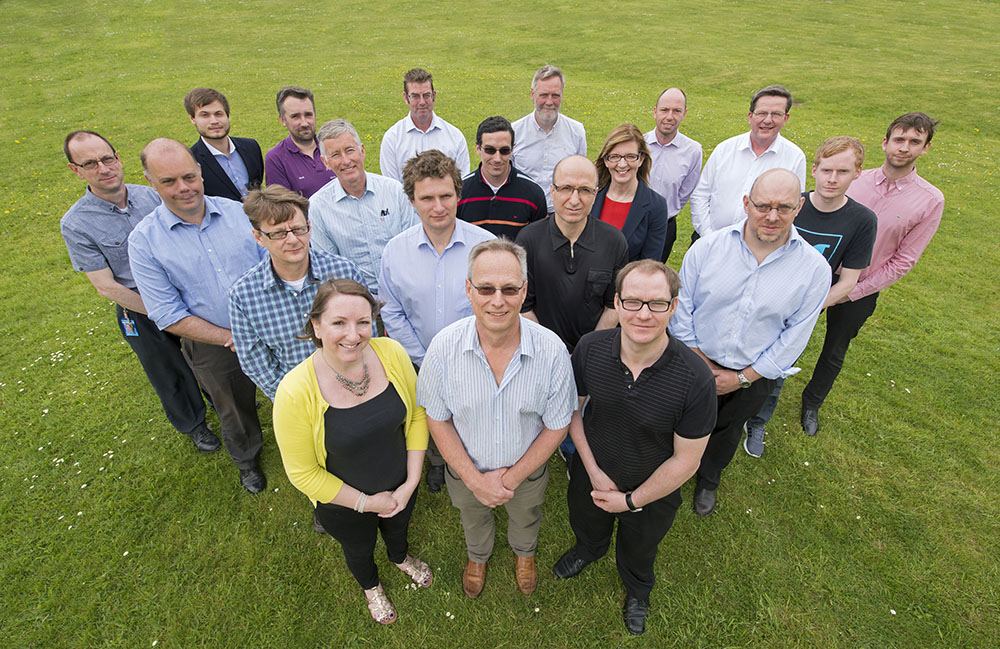

The OXSENSIS team